Hygiene Equipment for the Food Industry in the UK

Hygiene equipment for the food industry plays a critical role in protecting product integrity, preventing contamination and supporting compliance with food safety standards. From controlled hygienic entrances to boot washers and metal detection systems, the right solutions help food manufacturers and processors maintain strict hygiene protocols at every stage of production.

At GM Service Engineering, we supply and support a range of hygiene control equipment designed specifically for food production facilities, ensuring your operation remains safe, efficient and fully aligned with industry expectations.

Reliable Hygiene Control Across Food Production Environments

Maintaining high standards of hygiene in food production is not optional; it is fundamental to protecting consumers, safeguarding brand reputation and meeting regulatory requirements. In many facilities, hygiene control must begin before personnel even enter production areas and continue throughout the manufacturing and packing process.

Effective hygiene equipment for food industry environments supports:

Controlled personnel access into clean zones

Removal of contaminants from footwear and equipment

Detection of foreign bodies within finished products

Clear separation between high-risk and low-risk areas

These systems form part of a wider food safety strategy, working alongside HACCP procedures, cleaning schedules and quality assurance protocols.

At GMSE, we understand that hygiene control equipment must integrate seamlessly into existing workflows. The right solution should not slow operations down. It should reinforce process discipline while supporting productivity and compliance.

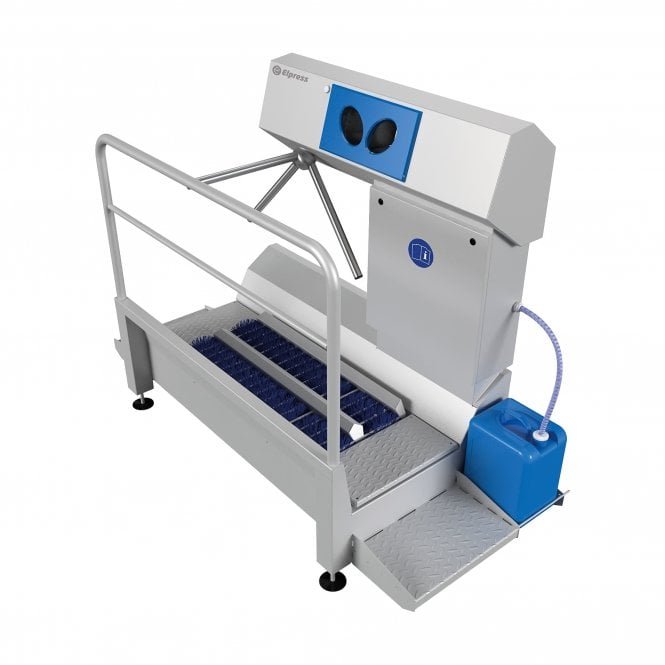

Boot Washers for Food Production Facilities

Footwear hygiene is one of the most common weak points in contamination control. In food production environments, boots can carry debris, bacteria and other contaminants between zones if not properly cleaned and sanitised. Boot washers form a critical part of access control into high-care and high-risk areas.

Designed specifically for food manufacturing and processing sites, boot washers automate the cleaning and sanitising of footwear before personnel enter controlled areas. Systems may include rotating brushes, water jets and dosing of cleaning agents to ensure thorough removal of contamination from soles and sides of boots.

Boot washers are commonly installed at:

Entry points to production areas

Transitions between low-risk and high-risk zones

Meat and poultry processing facilities

Dairy and ready-meal production environments

By integrating boot washers into hygiene workflows, facilities can significantly reduce the risk of cross-contamination while maintaining consistent hygiene standards across shifts.

We supply a range of boot washer systems suitable for food industry applications, with options designed to suit different facility sizes and throughput requirements. Our team understands how these systems fit within wider hygienic entrance layouts and can advise on selecting the most appropriate solution for your operational setup.

Hygienic Entrance Systems

In food production environments, hygiene control often begins at the point of entry. Hygienic entrance systems are designed to manage and enforce cleaning procedures before personnel access sensitive areas, helping to prevent contamination from entering production zones.

Unlike standalone cleaning equipment, hygienic entrances combine multiple hygiene functions into a single controlled access point. These systems may integrate:

Boot washing and sole sanitising modules

Hand washing and hand sanitising stations

Turnstiles or controlled barriers

Access interlocks that prevent entry until hygiene procedures are completed

By guiding staff through a structured hygiene process, hygienic entrance systems reinforce compliance and reduce the risk of human error. They are particularly valuable in high-care and high-risk food environments where strict segregation between clean and non-clean areas is required.

Hygienic entrances are commonly installed in:

Meat and poultry processing plants

Dairy production facilities

Ready-to-eat and high-risk food manufacturing

Large-scale food packing operations

For many facilities, these systems form part of a wider food safety and quality management framework. When properly integrated, they support HACCP protocols and demonstrate a proactive approach to contamination control.

GMSE supplies hygienic entrance systems suitable for food industry environments, helping businesses select configurations that align with site layout, staff flow and operational requirements. Our understanding of food production processes ensures that hygiene control measures enhance, rather than disrupt, productivity.

Food Metal Detectors for Contamination Prevention

While controlled entrances and boot washers help prevent contamination from entering production areas, metal detection systems play a critical role further along the process by identifying and removing foreign bodies before products leave the facility.

Food metal detectors are designed to detect metallic contaminants within raw ingredients, in-process products or finished goods. These systems are typically integrated into conveyor lines and production workflows, providing continuous inspection without interrupting throughput.

In food manufacturing, metal detection supports:

Protection of consumer safety

Compliance with retailer and regulatory requirements

Safeguarding brand reputation

Verification within HACCP and quality management systems

Modern metal detectors can identify ferrous and non-ferrous metals, as well as stainless steel fragments, depending on the application and configuration. They are widely used across sectors, including meat processing, bakery production, dairy manufacturing and packaged food operations.

GMSE supplies metal detection equipment suitable for food industry environments and understands how these systems integrate into wider production lines. From initial specification through to installation planning and ongoing support, we ensure equipment aligns with operational demands and safety standards.

How GMSE Supports Hygiene Equipment for Food Industry Operations

Selecting the right hygiene equipment for food industry environments requires more than choosing individual machines. It involves understanding workflow, zoning, compliance requirements and how different systems integrate across a facility.

We work with food manufacturers and processors to ensure hygiene control solutions align with operational realities. Whether you are installing new boot washers, upgrading hygienic entrance systems or integrating metal detection into a production line, equipment must be specified correctly and positioned effectively.

Our support can include:

Advising on suitable hygiene control configurations

Supplying new equipment designed for food production environments

Supporting installation planning and system integration

Ongoing servicing and maintenance where required

Working alongside site teams to ensure reliable operation

Food production environments demand durability, ease of cleaning and dependable performance. Downtime or system failure can have immediate operational and compliance consequences. That is why selecting appropriate, well-supported equipment is essential.

GMSE understands the standards expected within the food industry and the importance of maintaining hygiene protocols across shifts, teams and production cycles. Our approach focuses on practical, long-term solutions that support both compliance and productivity.

Hygiene Equipment for the Food Industry FAQs

-

Hygienic entrance systems control and enforce cleaning procedures before personnel enter production areas. By integrating boot cleaning, hand washing or sanitising and access control mechanisms, they help prevent contaminants from being introduced into high-care or high-risk zones. This structured approach reduces human error and strengthens hygiene compliance.

-

Boot washers remove debris, bacteria and other contaminants from footwear before staff enter controlled areas. In food manufacturing environments, footwear can transfer contamination between zones. Automated boot washing systems ensure consistent cleaning and sanitising, supporting segregation between clean and non-clean areas.

-

Food metal detectors are commonly integrated into conveyor systems within processing or packaging lines. They inspect raw ingredients, in-process materials or finished products to identify metallic contamination. This helps protect consumers, maintain retailer standards and support HACCP verification procedures.

-

Yes. Like all production equipment, hygiene control systems require regular inspection and maintenance to ensure reliable operation. Components such as brushes, dosing systems and detection units must function correctly to maintain hygiene standards and avoid operational disruption.

-

In most cases, yes. Many hygiene systems are designed to be modular and adaptable to existing layouts. Careful planning is required to ensure that entrance systems, boot washers or metal detectors integrate efficiently without disrupting workflow or creating bottlenecks.

-

Hygiene equipment is widely used across food sectors including meat processing, dairy production, bakery manufacturing, ready-meal production and high-risk food packaging operations. Any facility handling food products can benefit from structured contamination control measures.

Discuss Your Hygiene Equipment Requirements

If you are reviewing hygiene control procedures or planning upgrades within your facility, GMSE can help you assess suitable solutions for your operational needs.

From hygienic entrance systems and boot washers through to metal detection equipment, we work with food production businesses to ensure hygiene measures are both effective and practical within real-world environments.

To discuss hygiene equipment for food industry applications, speak with our team today.

Contact us to arrange a consultation or request further information.