The Burger Machine Blueprint for Catering Success

Introduction

If you're in the catering game and burgers are on the menu, there's one piece of equipment that can transform your efficiency and consistency: the burger machine. Whether you're running a small restaurant, mobile kitchen or looking to add burgers to your menu for the first time, the right commercial burger press machine can elevate your output, product quality and profitability.

In this guide, we’ll walk you through exactly how burger machines work, which types cater to your needs, and how to create perfectly-formed, juicy patties every time.

Why Burger Machines Matter in Catering

Burgers aren’t just a menu item, they’re a business strategy. Fast, familiar and customisable, they’re a staple across events, pop-ups, and high-volume kitchens. But success depends on speed, consistency, and presentation.

That’s where specialised equipment comes in. Using a commercial burger press or burger making machine ensures:

Uniform shape and weight across all patties

Faster preparation and less manual labour

Reduced waste with portion control

Easier freezing and storage

Professional appearance that matches customer expectations

If you’re still hand-pressing burgers or using small-scale tools, you’re likely leaving money on the table.

1. What Is a Commercial Burger Machine?

A commercial patty former is a professional tool designed to shape minced meat into patties with speed, precision and hygiene in mind. Unlike manual presses, these machines can be semi-automatic or fully automated, allowing for high-volume output without compromising consistency.

There are various types:

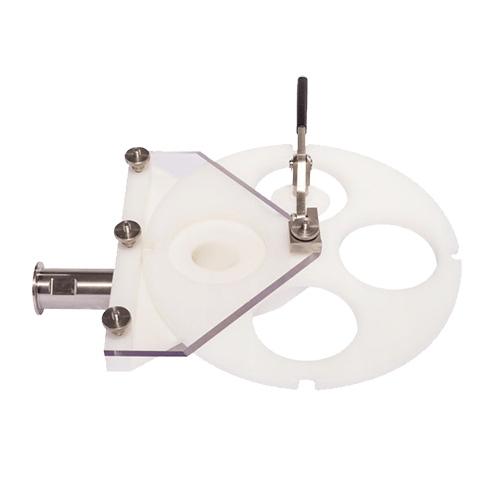

Manual lever press machines (entry-level commercial use, such as the Sirman SA150)

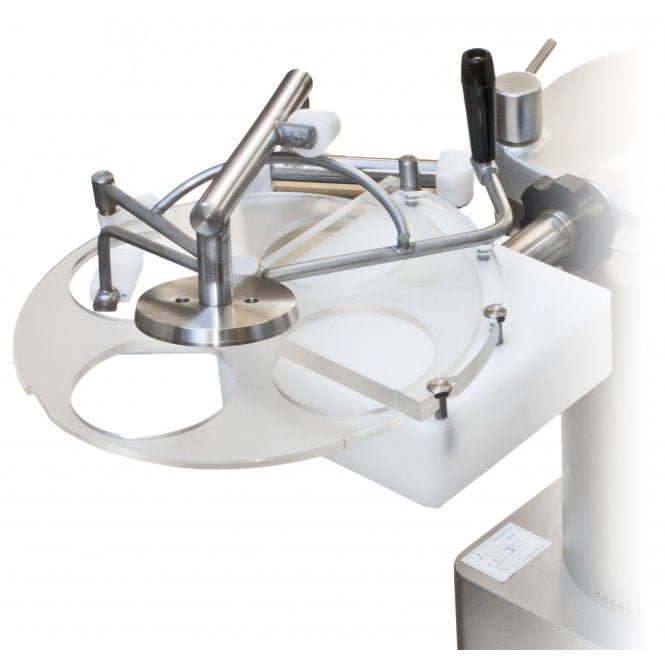

Semi-automatic burger presses (popular for mid-sized operations)

Fully automatic patty formers (like the Formatic R2200)

2. How Burger Machines Work

At their core, these machines work by compressing a portion of mince between moulds to create a uniform patty. Some machines allow customisation of weight, diameter and thickness.

Advanced models also:

Feed meat automatically from a hopper

Integrate conveyor belts for stacking

Insert sheets of burger paper between patties for easy storage

This automation is especially valuable for caterers managing bulk orders, seasonal peaks or food trucks.

3. Choosing the Right Burger Press Machine

When selecting the right burger making machine, consider:

Production Volume

Low (under 250/day): Manual or small semi-automatic models

Medium (250–1,000/day): Formatic or Mainca semi-automatic

High (1,000+): Fully automatic Formatic or Rex

Size & Storage

Do you have the space for a standalone machine or need something compact?

Meat Types

If you plan to use vegetarian or mixed blends, check if the machine supports this.

Ease of Cleaning

Machines with easy disassembly reduce downtime and improve hygiene.

4. How to Use a Burger Machine Step-by-Step

Here's how to get perfect patties every time:

Prepare your mix – Season and mix your meat thoroughly.

Load the hopper or mould – Ensure the machine is clean and ready.

Add burger paper – For stacking and freezing. Buy here!

Press or activate machine – Follow manufacturer instructions.

Collect and inspect patties – Check shape, thickness, and edges.

Clean machine after use – Maintain hygiene and longevity.

5. Top Brands: Formatic, Mainca, ABM & Rex

GMSE Ltd stocks a variety of burger machines, both new and refurbished, from industry-trusted brands:

Formatic

ABM

Rex

Mainca

Explore our available machines:

6. Common Mistakes to Avoid

Even experienced caterers can slip up. Avoid these pitfalls:

Skipping burger paper – Causes patties to stick and lose shape

Over-packing the hopper – Can damage the machine or reduce patty quality

Neglecting cleaning – Leads to build-up, hygiene issues, and machine wear

Buying too small – Underestimating your daily demand causes delays

Using machines for unsupported ingredients – Not all machines handle veg or fish patties well

💡 Tip: Speak to the GMSE team for advice on compatible machines for specific mixes.

7. FAQs

-

Load the seasoned meat into the machine, place burger paper if needed, and activate the press. Collect the patties and store them chilled or frozen.

-

Always use burger paper between patties. For non-automated machines, lightly oiling the mould can help.

-

They use high-quality meat with a good fat ratio (around 80/20), avoid over-handling the mix, and use machines that press but don’t compress the meat too tightly.

-

Consistency. Burger machines help ensure every patty is the same size and cooks evenly. Plus, pro kitchens use seasoning and precise temperature control.

Final Thoughts

Burger machines are no longer a luxury, they’re a necessity for any catering business that wants to stay competitive. From speeding up production to improving quality, a commercial burger press machine can completely transform your workflow and customer experience.

GMSE Ltd is proud to offer reliable, expert-vetted machines from leading brands — available both new and refurbished to suit all budgets.

Ready to upgrade your catering setup? Get in touch with your team today.